Top or Bottom Fill a Microbulk Tank, What's the Difference? The Mystery Explained:

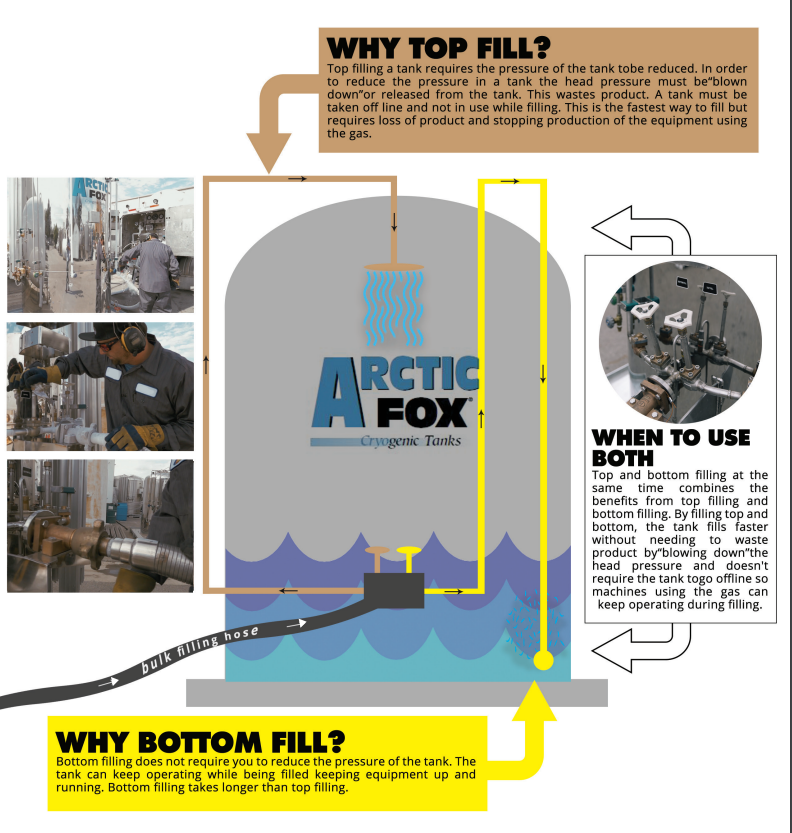

Cryogenic tanks are typically filled from the top using the blow down method. The blow down method is when the pressure of the tank is reduced by blowing out the head pressure of the tank in order to fill it. Blowing down a tank wastes product and in turn costs money. Top filling also requires taking the tank offline or to not be used while it is being filled because the tank cant keep pressure, which causes the customer using the tank to shut down and stop their operation during filling. However, the Arctic Fox tank enables the user to simultaneously fill from the top and bottom, eliminating the need to use the less efficient blow down method. The bottom fill method keeps the pressure up, allowing the user to keep the machine online and keeping their operation running since the Arctic Fox maintains the required pump pressure to keep operating. The top and bottom filling method does not require a tank to be blown down and therefore prevents loss of product during the filling process.

For customers such as laser cutting facilities that use nitrogen gas in their machines to cut metal products, the Arctic Fox tank is invaluable as it permits operations and production to flow smoothly throughout the entire filling process. Because the top and bottom fill capability maintains the necessary pressure levels during the filling process, the user can continue production without halting the use of the gas. This ensures a seamless filling period for the customer unlike the process required by other tanks that rely on the top fill method.

For customers such as laser cutting facilities that use nitrogen gas in their machines to cut metal products, the Arctic Fox tank is invaluable as it permits operations and production to flow smoothly throughout the entire filling process. Because the top and bottom fill capability maintains the necessary pressure levels during the filling process, the user can continue production without halting the use of the gas. This ensures a seamless filling period for the customer unlike the process required by other tanks that rely on the top fill method.

Additionally, the Arctic Fox tank features different hookup options. This flexibility allows multiple types of trucks to connect to fill the tank, including conventional micro bulk-trucks with a standard cryogenic hose and those with an inch and a half bulk hose. This way, users aren’t limited in what kind of trucks they can use to fill their tanks.

Throughout the entire process, the operator has complete control over the pump pressure of the Arctic Fox tank. With top and bottom filling capability, filling is much faster than any other method. And users can complete rapid tank fills without the use of specialized proprietary pumping equipment. The arctic fox tank was designed for filling to be a seamless and efficient process.

With the Ratermann Manufacturing Arctic Fox Tank you will be able to maximize both production and efficiency while minimizing costs to your customer’s company. The Arctic Fox tank’s top and bottom fill feature and duel blow down vents ushers in a smarter, faster & overall more efficient way to fill tanks allowing companies to fill tanks faster and make more deliveries per day. (For PDF of this article click here)

Click Here to watch a video showing the Arctic Fox Features >>

Fill Out this form to be contacted with more information about the Arctic Fox Tank: