When You Need a Vaporizer:

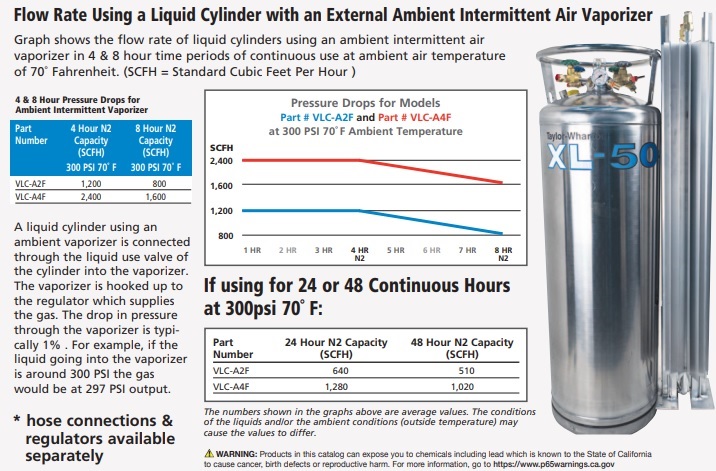

Short answer: If the demand of gas needed (also known as flow rate) is higher than the output of a liquid cylinder the pressure and flow rate will drop. Adding a vaporizer to the liquid cylinder increases the flow rate of the liquid cylinder while keeping the same pressure. Meaning the flow rate and pressure stays constant.

Longer explanation:

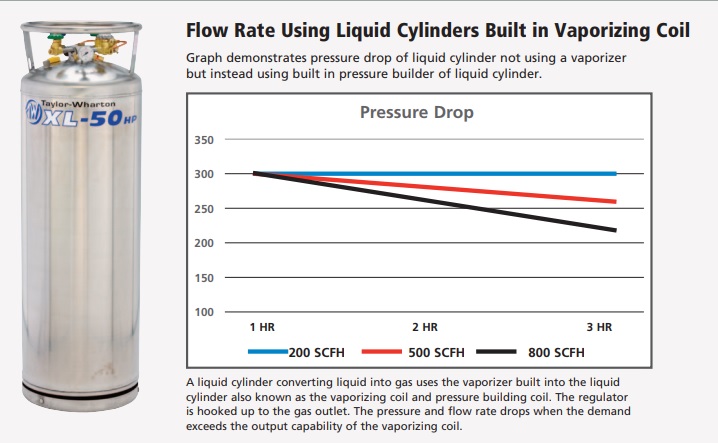

A typical 160 liter cryogenic liquid container with a medium pressure has an output of about 350 standard cubic feet per hour of liquid nitrogen. After the first hour of operating, the output of the dewar starts to slow because the container becomes cold. Warm air allows the container to convert the liquid into gas quickly. The lack of warm air drops the output of the tank after the 1st hour of use. If more than 350 standard cubic feet of liquid nitrogen is needed per hour, the dewar would be unable to keep up with the demand. The tank would start to over draw the vaporization. A scenario such as this is when you would use a vaporizer. A vaporizer allows you to continue to convert liquid into gas for long periods of time as oppose to being limited to a liquid cylinders standard output. If customers need a higher flow rate, a vaporizer can be attached to the liquid container and will generate a higher flow rate for a longer period of time.

Click here for the Printable PDF >>

Fill out this form to request more information about our vaporizers: