By: Lance Looper on January 26th, 2023

lubricants | ratermann mfg | Cryogenic Corner | cryogenic equipment | cryogenic valves

Liquid cylinder repair and maintenance can add up to big bucks for gas distributors – but it doesn’t have to. We have one simple tip that can keep cylinders in good working order and result in significant cost savings.

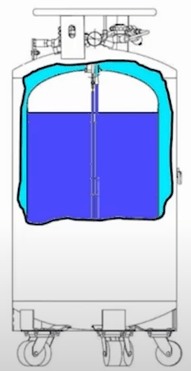

First, a quick review of the basic design element that makes a cryogenic cylinder work so well: an extremely strong vacuum between the inner vessel and the outer stainless-steel shell. As James Dewar discovered back in the late 1800s, that vacuum makes all the difference for the longevity of a cryogen.

Without a strong vacuum, the cylinder is essentially inoperable. Under normal conditions, a cylinder loses about 1-2 percent of its contents per day. But without that vacuum, cryogens boil off incredibly fast – almost like pouring liquid nitrogen into a bucket.

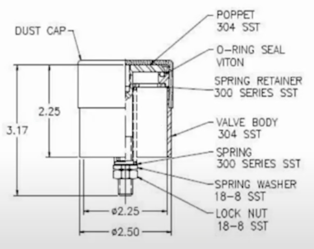

Nearly all cryogenic cylinders are manufactured with a vacuum port welded onto the crown, in varying diameters and sizes. Inside that port is a simple o-ring. Inevitably, dirt and exposure to UV rays compromises the o-ring’s integrity, causing them to dry out and slowly lose their vacuum quality.

Letting an o-ring deteriorate is what leads to very costly repairs and tank downtime. Whenever the tank goes in for a refill, make the following standard procedure:

Following that quick, simple protocol will keep your tanks in service and out of the repair shop. Curious about what a bad vacuum might look like? Check out this post on How to Tell if You Have a Bad Vacuum on your Dewar.

See our interactive liquid cylinder diagram with complete replacement parts list.

Shop our O2 safe lubricants, oils and pastes.