By: Lance Looper on May 16th, 2023

High Pressure? No Problem with Generant Master Valves.

Cryogenic Corner | cryogenic equipment | cryogenic valves | master valves | generant

Gone are the days when it took a box wrench to open and close a fill plant master valve, when the end of the day meant a sore hand and wrist from forcibly operating valves. The newly designed Generant High Pressure Master Valve takes that struggle away. Designed for the tough requirements of cylinder fill plants, manifold and piping system applications, the MV series valves are the best in the industry.

Easy to operate, with low torque.

The Generant High Pressure Master Valve can literally be opened with just one finger. A needle thrust bearing maintains low operating torque throughout the full pressure range while minimizing wear effects during mechanical load. It’s also quick to open, with just 2.5 full turns from closed to open positions.

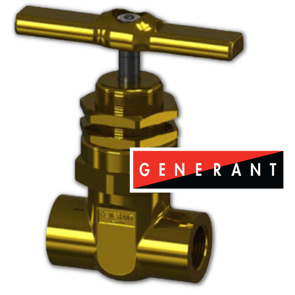

Removable bottom seat simplifies repairs.

In previous valve designs, the seat mechanism was built into the valve so that over time, the repetitive opening and closing caused the seat to embed itself into the body of the valve. When that valve eventually started to leak, you had to resort to cutting and welding to repair and replace.

The Generant High Pressure Master Valve’s removable seat negates all of that hassle. You can easily disassemble the valve, remove the seat and put in a new one – saving both money and time out in the field.

True reverse flow operation.

Many valves claim to be designed for reverse flow conditions, but will often fail when that’s attempted. Thinkimg about a cascade filling system with two trailers, the Generant High Flow Master Valve can truly handle flow in both directions thanks to a vented poppet and seal design. No one in the industry has done this before, which is what makes this valve so superior.

Optimized components for a long service life.

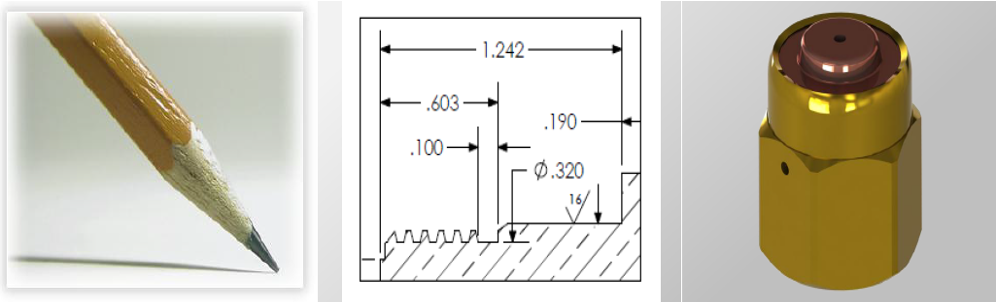

Designed with a non-rotating poppet and non-rising stem, the Generant High Pressure Master Valve maintains seat and seal integrity over a long service life. Series MV copper seal valves feature 45% more poppet thread engagement, resisting wear and providing a longer service life. When repairs are needed, fully-assembled cartridges are available for ultra-quick repairs in about three minutes. Valves are also adaptable to existing installations as a drop-in replacement and easy retro-fit.

Valves are also lubricated with Dupont Krytox, the strongest Teflon in the cryogenic market and built to hold up to all cryogenic applications.

Available in copper for oxygen safe operation.

The Generant High Pressure Oxygen Service Valve features a copper seat and has been third-party tested per ISO 7291 (O2 surge) and ASTM G175 (promoted ignition) and proven well-equipped for high pressure oxygen use – making everyone feel safer at the end of the day. The valve is also available with a PCTFE seal for positive sealing in non-oxygen applications.

More technical specs:

- Operating Pressure Range: Vacuum to 5,500 Psig at 70°F.

- Note: valves with NPSM connections (1” - 11.5 NPSM) are de-rated to 3,500 Psig due to the connection’s maximum pressure rating.

- Operating Temperature Range: -40° to 165°F (-40° to 74°C)

- 100% factory tested for internal and external leakage - no bubbles visible for 10 seconds with N2 gas at 2,500 PSI.

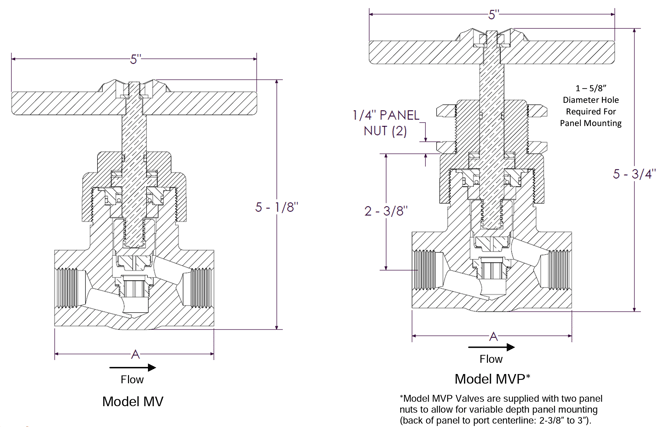

- Model MVP valves supplied with two panel nuts to allow variable depth panel mounting.

Shop Generant High Pressure Master Valves