By: Craig Pagano on May 31st, 2023

Flexible Hoses Part 2: The Right Hose for the Right Application

As we previously covered in Flexible Hoses Part 1: Understanding the Basics, it’s easy to order the wrong hose. There are a lot of factors that come into play when choosing a flexible hose for cryogenic or compressed gas applications, and it’s not uncommon for customers to get bleary-eyed when diving into the specifics of hose terminology.

Our last post focused on the common terms that come into play when choosing a cryogenic or high pressure hose, as well as the questions to ask when choosing a hose type. In this post, we’ll focus on the typical hose applications and the applicable hose materials, as well as highlight some common Ratermann hose options that are in-stock and ready to ship so you can install or replace a hose quickly and efficiently.

Common hose materials:

Cryogenic and compressed gas hoses come in a variety of materials. Your use-case will determine the most appropriate material. Here’s a quick run-down of the most common choices:

Rubber: This is the most inexpensive option, but the downside is high permeation rates. Thus, it’s not recommended for high-purity applications.

Thermoplastic: Another economical option, thermoplastic hoses are durable and flexible with reasonably low permeation rates. Thermoplastic is not recommended for oxygen use. See Ratermann hose type TPL for options.

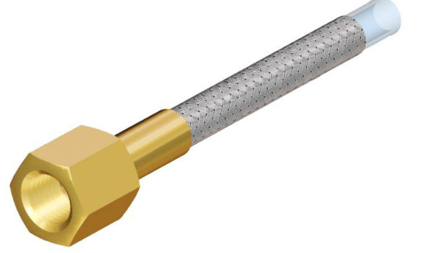

PTFE (Polytetrafluoroethylene): PTFE hoses are among the most popular high-pressure hoses in use. Commonly found in fill plants across the country, PTFE is durable and flexible while remaining cost-effective.

- PTFE inner core, 0.030 wall thickness

- One layer, stainless steel braid

- 3,000 PSI MAWP

- Brass end fittings - ¼” FNPT E/E (most common)

- Armor available for anti-kinking and to reduce whipping

PTFE Post Sintered: The ‘post sintered’ process re-bakes the PTFE at a controlled time and temperature, which increases the wall thickness and tightens the molecular bond of the PTFE, dramatically reducing effusion and diffusion. As an example, a ‘once-baked’ hose placed underwater will show bubbles as the gas permeates the hose. A post-sintered or ‘twice-baked’ hose won’t show escaping bubbles underwater, indicating zero permeation. This is also an economical option that’s flexible and suitable for most gases. Common applications include industrial fill plants, welding distributors, cradle six-packs and mixed fill racks, and is a good choice for helium and hydrogen.

Ratermann FPT family of hoses:

- PTFE Post sintered inner core, 0.040 wall thickness

- Two layers of stainless steel braid

- 3,600 PSI MAWP

- Brass end fittings - ¼” FNPT E/E

- Armor available for anti-kinking and to reduce whipping

- FPT-60P option offers four layers of braid for 6,000 PSI

Rigid Metal: Rigid metal hose types are only recommended for stationary applications. This hose type is heavily prone to cracking and leaking as a result of bending and flexing.

All Metal Corrugated: All-metal hoses utilize a metal corrugated inner core (typically 316 stainless steel or Monel). Metal hoses feature zero permeation, meaning no gas is lost – very important in static gas applications. This option is usually more costly, due to its components. Commonly used in helium and hydrogen applications. The Monel core is available for corrosive gases.

Caveat: All-metal hoses cannot exceed the 150 feet per second flow. If that rate is exceeded, the metal core results in a harmonic vibration and ‘singing’ that will eventually cause the hose to crack along the top ridge. Thus, it’s not recommended for tube trailers.

- All metal core, stainless steel

- 4,500 PSI MAWP

- Excellent option for corrosive gases

- Cannot exceed 150fps flow rate

Specialty options and unique applications.

Ratermann offers an exhaustive line of hose types from standard, off-the-shelf options to fully customized solutions. But there are a number of ready to ship options for more unique, yet still fairly common, applications.

PTFE conductive liner: Conductive-lined PTFE hoses feature an inner conductive line that dissipates static electrical charges. High resistivity fluids or gases at high velocity cause positive electrical charges to build on the inside of the PTFE liner. If that charge isn’t dissipated to the end of the hose, it will build until it arcs through the tube wall to the braid, which can cause catastrophic hose failure. A use-case example is acetylene.

Bulk delivery: A wide selection of widths are available from a half inch up to three inches for bulk transportation from air separation plants or general bulk transport.

Smart hoses: The Smart-Hose Safety System automatically closes the hoses ends in the event that the connection is broken. For example, if a driver pulls away from the plant without disconnecting, a mechanism in the hose will slam shut and prevent gas from spilling out and causing a dangerous and potentially life-threatening situation.

CO2 beverage: The CO2 beverage industry has gone through dramatic changes over the last 15 years, with most restaurants using small bulk or micro bulk tanks for external storage. The FDA moved to eliminate plasticizers from CO2 equipment, which could contaminate sodas. Ratermann has a full supply of FDA compliant hoses for the CO2 beverage industry.

Tube trailers: Tube trailers carry large quantities of compressed gases, which when in use can easily exceed the maximum velocity of 150fps flow rate. Ratermann offers PTFE lined tube trailer hoses and Monel tube trailer options that can withstand high working pressures (6,000 PSI) while maintaining durability and flexibility - trans fill - for when flow is excessive more than 150/feet per second.

Tethering: Many companies are now requiring tethers to prevent on-the-job accidents if a hose ruptures. The tether prevents a ruptured hose from whipping around and potentially lacerating or lethally injuring anyone in the vicinity.

Hand tights and swivels: A host of additional options are available to prolong hose service life and make operation easier. Hand and tight options provide an easy to grip tightening ring so a wrench isn’t required.

Swivels protect hoses from kinking and eventually breaking. Anytime you kink or bend a hose, you further compromise the hose integrity. Swivels are beneficial in high-use situations like a medical fill rack, which is constantly on and off filling cylinders. The swivel prevents torque of the hose, which prolongs life span.

Ratermann has the hose you need! Use our Hose Builder tool or jump straight to our extensive flexible hoses selection.