Does your hose need to be replaced? Here are the top warning signs.

At Ratermann, we pride ourselves on selling high-quality products for use in the industrial gas & cryogenic industry – including our line of compressed gas and cryogenic hoses. That said, even the best high-pressure industrial hose won't last forever. Though it isn't hard to overlook the need for hose maintenance and replacement, hoses put to work beyond their useful lifespan can cause severe problems for your facility, so regular inspection is vital.

If you're not sure if your hoses have seen better days, read on! We'll give you advice on when it's time to replace your PTFE, ETFE, and "all metal" hoses, along with signs of internal or external wear that you should keep in mind.

If you're not sure if your hoses have seen better days, read on! We'll give you advice on when it's time to replace your PTFE, ETFE, and "all metal" hoses, along with signs of internal or external wear that you should keep in mind.

Keep An Eye Out for These Warning Signs

Are you wondering where to start when it comes to hose maintenance? An excellent first step is to begin visually inspecting your hoses regularly. Based on your exact line of work and your level of hose usage, this process can occur once a day, week, or month.

At this stage of the maintenance process, you may spot a few telltale signs that your hose may be having problems. These include:

Discoloration

If you notice markings like freckles or spotting on your industrial hose, don't ignore them! These can indicate that your hose has been in contact with foreign matter, potentially including a leak check solution. That's not necessarily a problem in and of itself, but if you don't mix these solutions to their manufacturer's recommended proportions, they can damage jacketed hose braids.

Kinking

The most common causes of hose kinks are excessive bending or stress – both of which can affect a hose's ability to do its job. So, when you notice kinks or major bends in a hose, it's time to think about replacing it.

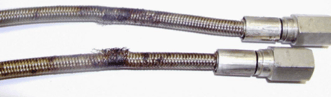

Braid Integrity Issues

The stainless-steel braid in your armored hose plays a crucial role – it allows the inner hose core to handle the kind of pressure typical of industrial environments. Once you find any breaks on a hose's braid, no matter how small, you should replace it as soon as possible.

Thread Problems

Make sure to include hose threads in your visual inspection routine! If you notice issues like cross threads or metal shavings, your hose must be removed and replaced. (To ensure your fittings meet specifications, you may want to buy a thread gauge.)

Put Your Hoses Under Pressure

While regular visual inspections can be beneficial, they can't tell the whole story on their own. So, in addition to this process, it's a good idea to run pressure tests on your hoses.

For leak tests, you'll need to check your hose for indications that it is leaking under pressure. Ratermann offers quite a few leak check solutions designed to work well under high pressure - you'll want to make sure to choose the one that's right for your situation. As we mentioned earlier, it's also critical to make sure you're mixing your solution to our recommended proportions!

You can use several gases for pressure testing, but the best choice for the job is helium. This gas is ideal for pressure tests thanks to its small molecules, which can slip through leaks other gases may not be able to. The one downside is that helium can be expensive - fortunately, if money is an issue, you can use other inert gases instead. On the other hand, avoid using compressed air/oxygen (or any other gas that may contain impurities) for pressure testing.

Know Your Hose's Lifespan!

Once you've implemented visual inspections and leak/pressure testing, you should have a better idea of what hoses you need to replace in your facility. However, there's one more thing you should be aware of – that is, how to estimate a hose's life expectancy. Knowing how to assess this allows you to understand how often you'll need to replace hoses, making life even easier for you.

On average, you should replace hoses every five years. However, the useful lifespan of a hose is determined by a few different factors, including the number of cylinder changes it goes through daily. For example, a hose experiencing four cycles per day will have an expected lifespan of 24 months. Meanwhile, a hose experiencing 20 cycles per day will have an estimated life cycle of 12 months. Just remember to be proactive when it comes to hose replacement – it's always best to replace a hose before it fails than after!

Do you want to find more information about your industrial or cryo hose? These hoses are legally required to list their manufacturer's name, date of manufacture, and maximum pressure. This information is often engraved or stamped on a hose's collar.

Choose Ratermann for Your Hose Replacement Needs

After you put these tips into action, you'll be rewarded with an industrial facility that's functioning at tip-top shape. Your hose inspection process may take a bit of extra time, but it won't be long before this hard work pays off.

If you need to replace industrial hoses, Ratermann can help! We offer a full range of hoses for many different industrial applications, including armored hose, jacketed hose, vacuum insulated hose, and more. Additionally, we can supply related products like leak check solutions.

Not sure if you're using a transfer hose that's suitable for the job? Our hose builder makes it easy to find the hose you need based on application, gas type, pressure rating, casing, and length. To double-check that your hose is well-suited to the application you need, give our service representative a call at 1-800-264-7793.