Atmospheric Gas Packaging, What is it?

industrial gas supplies | Beverage Solutions | Cryogenic Corner | Fill Plants

Atmospheric gas packaging is a growing technology that is done by manipulating gases to remove oxygen from a high barrier or permeable package. It is achieved by using inert gases including nitrogen, carbon dioxide, and exotic gases such as argon or helium to inject and remove multiple times to eliminate until the oxygen is eliminated. It is also known as modified atmosphere packaging, protective atmosphere packaging, reduced oxygen packaging, and gas flushing.

AGP OVERVIEW

One of the primary applications for atmospheric gas packaging is food preservation, as modified atmospheres are the most natural way to protect perishable food against spoilage. To keep food fresh for as long as possible without additives, processors and marketers of food products utilize atmospheric gas packaging to carefully controlled mixed gases that significantly slow down the process of food decay by inhibiting the growth of microbes and processes of oxidation. With atmospheric gas packaging, the packager can prevent the usage of chemical additives for the preservation of perishable goods. Atmospheric gas packaging can be utilized to keep foods freshly stored in bags, cans, boxes, bottles, cardboard, or plastic. Another application is for packaging used to store marijuana. Marijuana packages are flushed of oxygen and often filled with nitrogen to serve as a protective cushion. This nitrogen packaging keeps the marijuana fresh and free of molds for an extended period of time, and maintains the shape so that the package contents are not crushed

One of the primary applications for atmospheric gas packaging is food preservation, as modified atmospheres are the most natural way to protect perishable food against spoilage. To keep food fresh for as long as possible without additives, processors and marketers of food products utilize atmospheric gas packaging to carefully controlled mixed gases that significantly slow down the process of food decay by inhibiting the growth of microbes and processes of oxidation. With atmospheric gas packaging, the packager can prevent the usage of chemical additives for the preservation of perishable goods. Atmospheric gas packaging can be utilized to keep foods freshly stored in bags, cans, boxes, bottles, cardboard, or plastic. Another application is for packaging used to store marijuana. Marijuana packages are flushed of oxygen and often filled with nitrogen to serve as a protective cushion. This nitrogen packaging keeps the marijuana fresh and free of molds for an extended period of time, and maintains the shape so that the package contents are not crushed

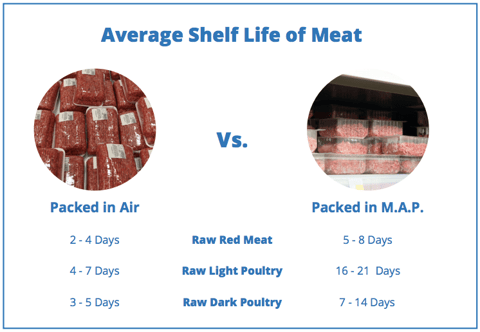

There are numerous advantages to atmospheric gas packaging. In addition to increasing the shelf life of perishable food, the practice reduces the growth of germs, maintains the form and texture of the food, and retains the color and nutritional content of the food. There are different gases used in M.A.P , such as Carbon dioxide and Argon, the most commonly used gas is Nitrogen. The type and proportion of gas used in the packaging depends on what food is in the package and how quickly the food would decompose without the packaging. Companies use complex machinery to remove gas from what is referred to as the packaging chamber and replace it with other precisely measured gases. It is a highly advanced process to measure the gases so that the right formula is achieved and risk of gas leakage is eliminated. Because of these technologies, the United States enjoys the safest food supply in the world.

There are numerous advantages to atmospheric gas packaging. In addition to increasing the shelf life of perishable food, the practice reduces the growth of germs, maintains the form and texture of the food, and retains the color and nutritional content of the food. There are different gases used in M.A.P , such as Carbon dioxide and Argon, the most commonly used gas is Nitrogen. The type and proportion of gas used in the packaging depends on what food is in the package and how quickly the food would decompose without the packaging. Companies use complex machinery to remove gas from what is referred to as the packaging chamber and replace it with other precisely measured gases. It is a highly advanced process to measure the gases so that the right formula is achieved and risk of gas leakage is eliminated. Because of these technologies, the United States enjoys the safest food supply in the world.

Market for AGP

According to the most recent market report published by Persistence Market Research, ‘Active and Modified Atmosphere Packaging Market: Global Industry Analysis and Forecast 2016-2024, the atmospheric gas packaging industry for meat, poultry and seafood is projected to register 1.5x growth in revenue over the next ten years between 2016 and 2026, and is forecasted to dominate the market throughout this period. At the end of 2016, the market value for atmospheric gas packaging was $17 billion.

According to the most recent market report published by Persistence Market Research, ‘Active and Modified Atmosphere Packaging Market: Global Industry Analysis and Forecast 2016-2024, the atmospheric gas packaging industry for meat, poultry and seafood is projected to register 1.5x growth in revenue over the next ten years between 2016 and 2026, and is forecasted to dominate the market throughout this period. At the end of 2016, the market value for atmospheric gas packaging was $17 billion.

The atmospheric gas packaging is expected to remain lucrative in the next decade as it is the favored packaging option for fresh food products that have serious demand among consumers. Companies that produce dairy, meat, poultry, fruits, vegetables and frozen foods prefer gas packaging over other options. Processed food products are currently estimated to account for 15% of total active atmospheric gas packaging market share, and this is only expected to grow as consumer spending increases. Atmospheric gas applications have reached maturity in some food applications including coffee, snack, and processed meats, but the is robust for refrigerated, prepared convenience foods that consumers are increasingly demanding. The fastest growing categories here include freshly cut produce, cheese products, and prepackaged sandwiches. Atmospheric gas packaging is especially applicable when packaging products that are designed to be “natural” or reduced in preservatives.

According to MicroMarketMonitor, North America and Europe have the strongest existing modified atmosphere packaging markets, whereas the rest of the world are the growing markets. North America, the largest segment, constitutes 32.2% of the market. The Asia-Pacific market is also promising as it is projected to grow at the highest compound annual growth rate (CAGR) of any region in the world. In 2015, the atmospheric gas packaging market by application was led by convenience food with a market share of 24.9%.

Opportunities for Gas Suppliers:

For gas suppliers, the expanding atmospheric gas packaging market provides a great business opportunity. Companies in this space are constantly looking for a reliable nitrogen supply to keep their company running as finding this consistent supply can be a challenge.

In addition to packaged foods, the growing packaged marijuana industry is a focus area for companies in this space. Atmospheric gas packaging keeps marijuana fresh for a longer period of time by minimizing the effects of sunlight, oxygen, moisture and heat. The packaging helps to maintain taste and color, providing a more preferable option to consumers than traditional storage practices. Companies typically invest in a quality nitrogen flushing and sealable unit for marijuana packaging that range from $5,000 to $35,000. Because M.A.P companies rely on a large nitrogen supply, companies typically invest in micro bulk or mini bulk tanks. Marijuana dispensaries are eager to work with companies that offer atmospheric gas packaging to set themselves apart from the competition. As laws surrounding both medicinal and recreational marijuana continue to evolve, the market opportunity for gas suppliers will continue to grow as well.